- Home /

- CONSUMABLES /

- CONSUMABLES - MISCELLANEOUS /

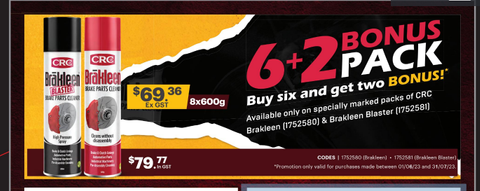

- CRC BRAKLEEN BONUS 6 + 2 X 600G

- ABRASIVES & ADHESIVES

- BEARINGS

- BUSHES

- CHAIN & SPROCKETS

- CLEARANCE

- CONSUMABLES

- CUTTING TOOLS & FITTINGS

- FASTENINGS

- FOOD GRADE PRODUCTS

- GENERAL

- OIL SEALS

- PNEUMATICS

-

TOOLS

- CUTTING TOOLS

- GENERAL

-

HAND TOOLS

- ACCESSORIES

- AUTOMOTIVE TOOLS

- BARS

- BENDING

- CLAMPS

- CLEANING

- CUTTING

- DRILLS

- FILES

- HAMMERS

- HAND TOOL - ACCESSORIES

- HAND TOOLS - CLEANING

- HEX KEY SETS

- HEX KEYS

- IMPACT BIT

- IMPACT DRIVERS

- INSPECTION TOOLS

- INSPECTIONS TOOLS

- JACKS

- LIGHTING

- MEASURING

- PLIERS

- PULLERS

- PUNCHES

- RATCHETS

- RIVETERS

- SAWS

- SCREWDRIVER SETS

- SCREWDRIVERS

- SIDE CUTTERS

- SOCKET SETS

- SOCKETS

- SOLDERING

- SPANNER SETS

- SPANNERS

- TOOL BOXES

- TOOL SETS

- TORX & HEX BITS

- VICES

- WINCH & HOIST

- WRENCHES

- POWER TOOLS & PARTS

- V BELTS & PULLEYS

- WELDING

CRC BRAKLEEN BONUS 6 + 2 X 600G

Description

CRC Brakleen is a powerful, heavy duty cleaner and degreaser for brake, clutch parts and general mechanical equipment. It is formulated to quickly and safely dissolve and flush away grease, oil, brake fluid, transmission fluid, hardened deposits and other contaminants, without the need for disassembly. It safely settles and removes hazardous brake dust.CRC Brakleen is non-staining, non-corrosive, leaves no residue and evaporates quickly.CRC Brakleen stops disc brake squeal and noise caused by contaminants, eliminates clutch slippage and helps brakes last longer and perform better. Tests by an independent laboratory show that the proper use of Brakleen brake cleaner improves brake efficiency by reducing stopping distances by as much as 24.3%.CRC Brakleen is ideal for removing grease and contaminates from CV joints and wheel bearings and can also be used to clean, degrease or flush away built up dirt, grease and oil from workshop equipment, tools, other mechanical or industrial machinery and electrical contacts. (Equipment must be de-energised before cleaning. Fully ventilate equipment before re-energising equipment).